Damp proofing in Construction is a type of moisture control applied to building walls and floors to prevent moisture from passing into the interior spaces. Damp problems is one of the most frequent problems encountered in majority of homes in Uganda. Damp proofing is a material that resists the passage of water with no hydro-static pressure. Generally, it keeps moisture out of a building where vapour barriers keep interior moisture from getting into walls.

Damp penetration is one of the most serious defects in buildings and if not checked it may cause; deterioration of structure, damage to finishing and may adversely affect the health of the occupants.

Causes of dampness in walls are due to number of reasons. These are;

i. Rising damp. In old buildings, damp may rise up walls because of the lack of damp-proof course (DPC). In newer buildings, rising damp may occur through a defective damp-proof course, by an external rendering or mortar droppings in the cavity. Damp may also penetrate a solid floor in the absence of a damp-proof membrane (DPM) in floor properly.

ii. Water introduced during brick laying and plastering. The walls often remain damp until a summer season has passed.

iii. Penetration through roofs, parapets and chimneys. Tiled roofs may admit fine blown snow and rain particularly in exposed situations whereas parapets and chimneys can collect and deliver water to parts of the building below roof level. The remedial measures for this problem include laying tiles to an adequate pitch angle, securely fixing the tiles and provision of a generous overhang at the eaves. The parapets and chimneys must have adequate damp-proof courses and flashings.

iv. Penetration through walls. This penetration occurs mostly in external walls and its mostly caused by exposure to diving rain, wet wind, and sometimes excessive wetting from a leaking gutter or downpipe. To overcome this, building regulations recommend the construction of thicker solid brick external walls, rendering the external surface of the walls or construction of cavity walls.

v. Leaks in a plumbing system. Dampness may result from leaking cold or warm water pipes in the building.

Damp proofing is accomplished in several ways including;

Ø Damp proof course (DPC). This is a barrier through the structure by capillary action such as through a phenomenon known as rising damp. Rising damp s the effect of water rising from the ground into your property. Damp proof courses may be horizontal or vertical and a DPC layer is usually laid below all masonry walls, regardless if the wall is a load bearing wall or a partition wall.

Ø Damp proof membrane (DPM). This is a membrane material applied to prevent moisture transmission. A common example is polyethylene sheeting laid under a concrete slab to prevent the concrete from gaining moisture through capillary action. A DPM may be used for the DPC. The difference is that DPC’s are in strip form while DPM’s are in wide sheet form.

· Characteristics of damp proof course include; (1) it should be impervious and durable, (2) it should have a reasonable degree of flexibility to prevent fracture with building movement, (3) it should have case of application and ability to withstand load, and (4) it should be available in the sheets at a reasonable cost.

· Types of damp proof courses are; (1) those below ground level to prevent the entry of moisture from the soil, (2) those placed just above ground level to prevent moisture creeping up the wall by capillary action/ rising damp, (3) those placed at openings, parapets and similar locations to exclude the entry of the rain water which falls directly onto fabric of the structure.

Ø Integral damp proofing in concrete involves adding materials to the concrete mix to make the concrete itself impermeable.

Ø Surface coating with thin water proof materials for resistance to non-pressurized moisture such as rain water or a coating of cement sprayed on such as shotcrete which can resist water under pressure.

Ø Cavity wall construction; such as rain screen construction, is where the interior walls are separated from the exterior walls by a cavity.

Ø Pressure grouting cracks and joints in masonry materials. Pressure grouting involves injecting a grout material into generally isolated pore or void space of which neither the configuration nor volume are known. The grout may be cementitious, resinous or solution chemical mixture. It’s used to strengthen or reduce the water flow through a formation. It’s also used to correct faults in concrete and masonry structures.

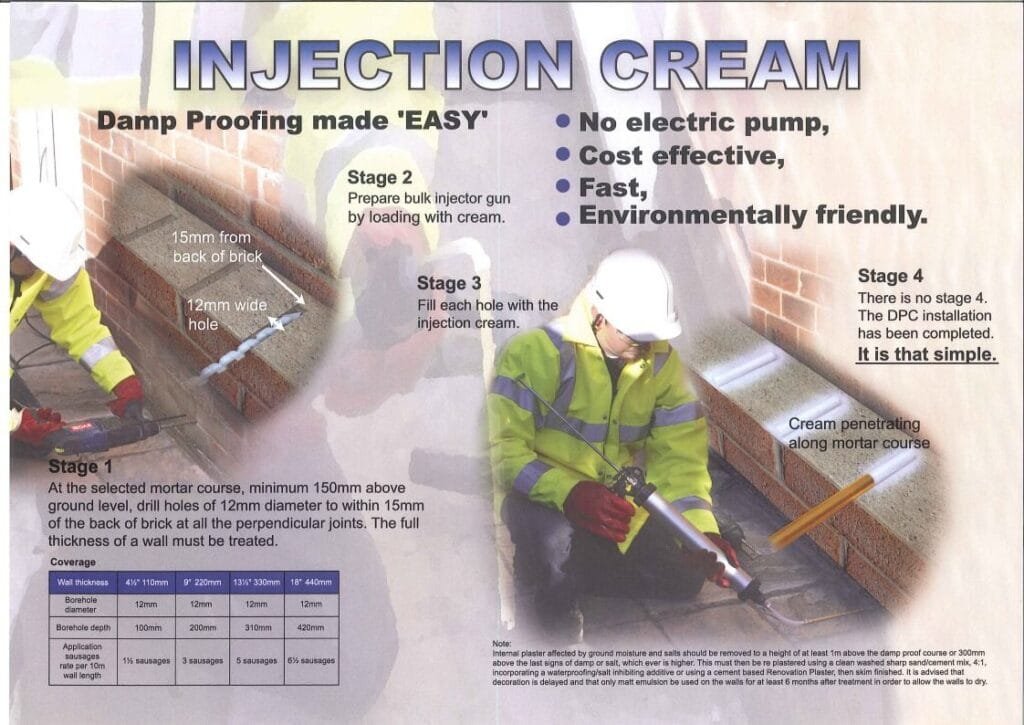

- The injection cream is a recently new development in damp proofing that is much easier to install than traditional techniques, cost effective and easy way to treat rising damp. It also reduces surface condensation and is very ideal for kitchens, bathrooms and the like.